We offer:

-Low frequency and DC magnetic field surveys below 10 kHz

-On site surveys and investigation of magnetic field issues

-Specification, design and validation services for magnetic screening and shielding

-Identification and resolution of earthing and bonding problems affecting the performance of Faraday cages

-Testing and evaluation of LF and DC magnetic screens, shields and Faraday cages

Locations include:

-Medical Imaging

-Neuroscience facilities

-Research labs and production environments

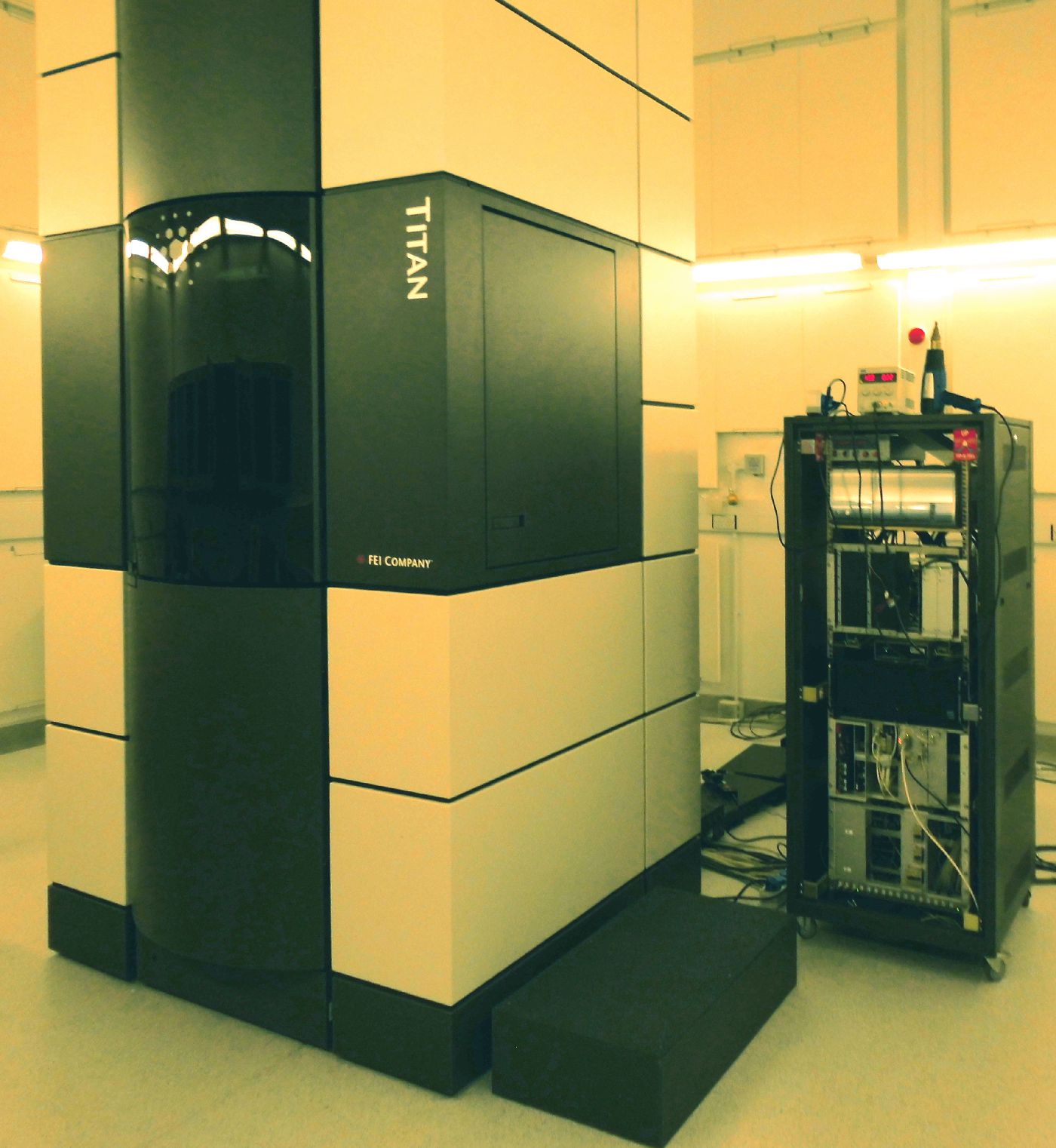

-Electron microscopes, spectroscopes and lithography systems

- Complex buildings for media

- Sensitive instrumentation and measurement